About Us

HAJI HASSAN REINFORCEMENTS

Established in 1981, Haji Hassan Reinforcement is the major supplier of cut and bend reinforcements in the Kingdom of Bahrain. HHRF additionally supplies straight rebars of all sizes and welded wire-mesh fabric in large quantities.

In order to cope up with the construction boom and heavy demand for cut and bend rebar at the Kingdom of Bahrain, HHRF had installed the latest computer controlled shear line machine with a capacity of more than 100 tons per day.

Furthermore, HHRF is using the most sophisticated automatic bending machines available. With combination of American, German and English made machines, the company can now undertake any project, be it large or small.

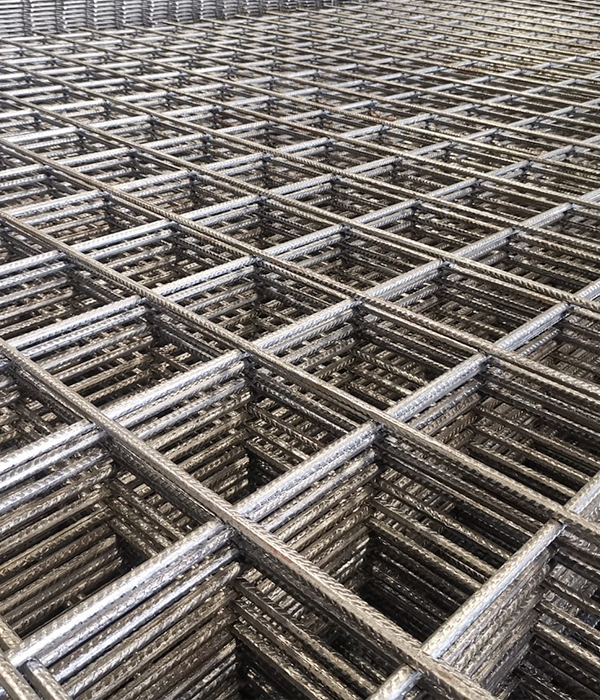

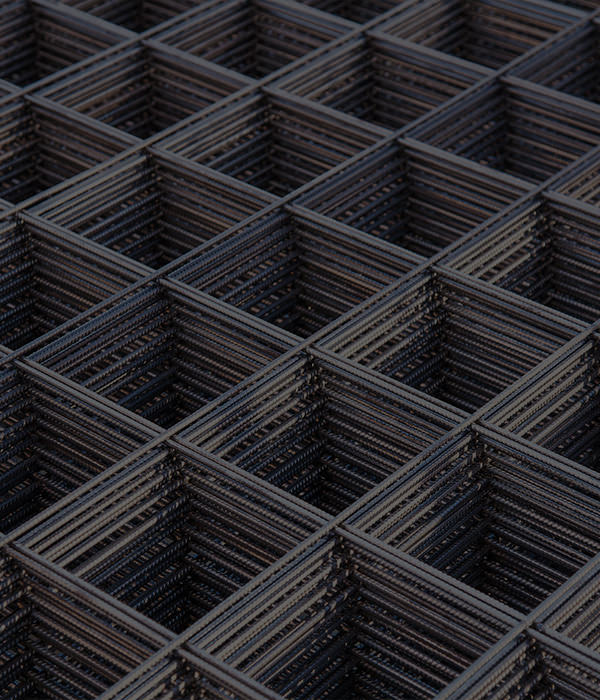

Additionally, HHRF has installed a mesh welding plant which has a capacity of producing welded mesh to specification BS 4483 in standard sheet sizes of 2.4 x 4.8 m., and can easily produce 8 - 12 tons per day. HHRF have also installed a semi-automatic straightening and cutting machine.